SSC Laser Cutting has come a long way since operating from a portacabin in September 2000, but one thing has always remained consistent; SSC has always strived to become one of the UK’s leading laser cutting sub-contractors.

Over the past two decades, from our humble beginnings, we have expanded through an aggressive growth strategy based on customer requirements and a rapidly growing market. Team members have come and gone, but throughout all of this, two things have always remained consistent, our willingness and drive to provide top-quality laser cutting to thousands of customers, and continual investment in the most up-to-date laser cutting technology to ensure that our service proposition continues to be world-class.

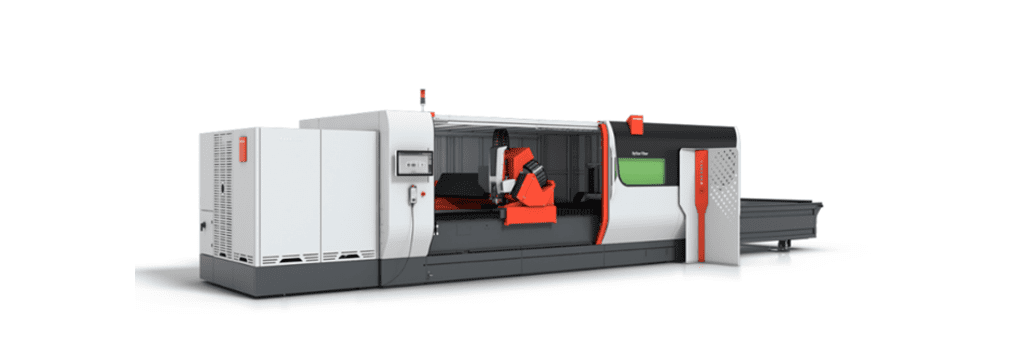

If you follow our social media channels, you will have undoubtedly seen that we had taken delivery of a new 18,000 m³ nitrogen tank back in March. This was planned in preparation for the delivery of our cutting edge Bystar 12KW Fibre Laser.

Not only did we need to make accommodations for the new nitrogen tank – but we’ve also had to completely redesign the shop floor to make way for the new machine. We’ve spent time to make sure that we can help maximise the efficiency of the new machine, helping to increase our throughput. We have done all this, without missing a beat in serving our customers.

Faster Laser Cutting

This new machine is fast! The new installation will allow the team at SSC to laser cut materials from our core range up to 20% faster than our 10kw machine. SSC can now cut mild steel, stainless steel and aluminium materials up to 30mm thickness and even brass and copper up to 15mm, much more efficiently.

Combined with the speed benefits, the new machine is a newly designed model with a slimmer, improved cutting head, with fewer components and more state-of-the-art technology.

The new technology, head build and slimline design will further minimise the risk of collision with tipping parts, and further minimises the possibility of contamination that is produced during the cutting process. All of these things will further decrease the need for any emergency maintenance and laser downtime and so the net effect of this, for you our customer, is further improved cut quality and efficiency.

The Bystar 12KW also features optimal cooling, which reduces thermal stress when in use. This feature allows SSC to sustain a higher level of precision for more extended periods, as the beam is stabilised, meaning that our customers will continue to receive the highest quality cutting that they have come to expect from SSC.

The machine also has new Beamshaper technology. This allows you to cut thicker Mild Steel, up to 30mm, better, faster and more efficiently than ever before and helps provide an exceptional cut quality.

SSC predicts that the new additional machine will not only help increase our capacity, productivity and efficiency but also improve our lead times even further, so we can continue to provide the high-class service we offer our customers and deliver exactly what you need when you need it.

If you have any questions regarding laser cutting or an upcoming project requiring a laser cutting sub-contractor, contact the team at SSC Laser today. Our team are on hand to help you, whatever the size of your project or design.

T: 01889 270241

E: sales@ssclaser.co.uk